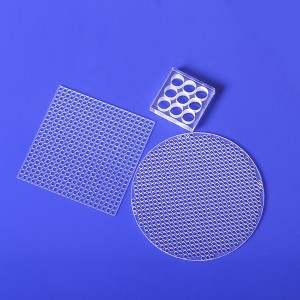

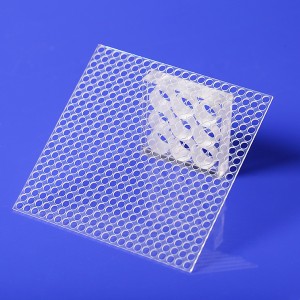

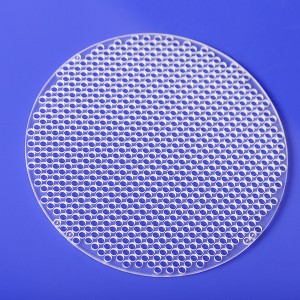

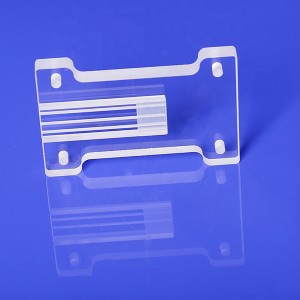

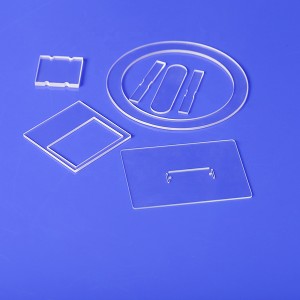

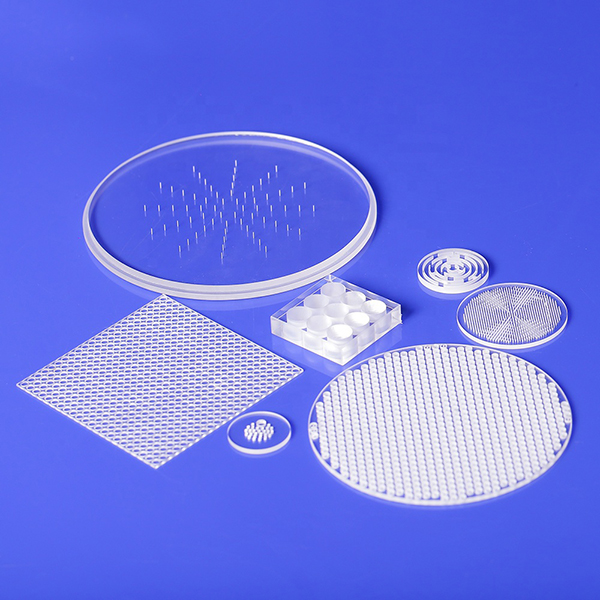

CNC Machining JGS1 Fused Silica poleiti e nang le lesoba

The High Precision of CNC Machined e ka fana ka likarolo tse ntle tsa khalase ea quartz, joalo ka ho slotting, ho cheka le ho betsa. Molemo ke hore ho nepahala ha ts'ebetso ho phahame mme ho ka finyella litlhoko tsa bareki ba fapaneng.

1.Custom Design le Tailor-Made lia amoheloa.

2. Lisebelisoa tse ngata tse kang Quartz, Silika e Fused, Likhalase tse sa tšoaneng tsa Optical

3.The High-Precision Fabricated Parts fana ka boleng bo phahameng le nako e telele ea bophelo.

China Optical Quartz Glass Kereiti

| Lebitso | Kereiti e tsamaellanang | Sebopeho |

| Khalase e Hole ea Ultraviolet Optical Quartz | JGS1 | Ho pepeseha ho ultraviolet le mahlaseli a bonahalang; ha ho na sehlopha sa ho monya sehlopheng sa 185-250nm; sehlopha se matla sa ho monya sehlopheng sa 2600-2800nm; mahlaseli a khanyang a sa khanyeng, a tsitsitseng. |

| Khalase ea UV optical quartz | JGS2 | Ho pepeseha ho ultraviolet le mahlaseli a bonahalang; ha ho na sehlopha sa ho monya sehlopheng sa 200-250nm; sehlopha se matla sa ho monya sehlopheng sa 2600-2800nm; mahlaseli a khanyang a sa khanyeng, a tsitsitseng |

| Khalase ea infrared optical quartz | JGS3 | Ho pepeseha ka mokhoa o bonahalang le oa infrared spectrum; ha ho na sehlopha se hlakileng sa ho monya sehlopheng sa 2600-2800nm; |

Lintho tse bonahalang

Silika e kopantsoeng ea UV

Schott borofloat 33 khalase

Sapphire

Khalase e futhumetseng

Tlhaloso

Re ka etsa mefuta e mengata ea likarolo tsa quartz ho latela ho taka.Hoo e ka bang likarolo tsohle tsa quartz li etsoa ke machining a CNC, karolo e nyenyane e thusoa ke lisebelisoa tsa laser. Re sebetsa le ho fana ka mefuta e mengata ea bokhoni ba ho sebetsana le lisebelisoa tsa khalase.

Litsi tsa ho sila tsa CNC tse nang le boholo bo boholo ba tafole e le 24" x 36"

Litsi tsa ho sila tsa Jet tsa Metsi tsa CADCAM tse nang le boholo ba tafole ea 26" x 52"

Lihlahisoa tse bontšitsoeng

Lisebelisoa

Ho hatisa le ho daea

Lifensetere tsa mahlo

Lipoleiti tse tšehetsang mocheso oa mocheso

Lithako bakeng sa likamore tsa karabelo

Lipoleiti tsa sekoahelo sa quartz

Lisebelisoa tse hanyetsanang le mocheso lisebelisoa tsa semiconductor

Lisebelisoa tsa lisebelisoa tsa ho roala ka vacuum

Sebopeho sa Quartz

| SIO2 | 99.99% |

| Coefficient ea Katoloso | 5.54 x 10-7 (K-1) |

| Strain Point Mocheso | 1343 Degree K |

| Softening Ntlha | 1933 Degree K |

| Thermal Conductivity | 1.37 W/m 0K |

| Annealing Point Mocheso | 1433 0K |

| Kakaretso ea Mocheso o Khethehileng - | 771 J/kg.K |

| Mocheso o nepahetseng oa ho sebetsa | 1423 - 1473 0K |

| E khethehileng Heat Conductivity | 1.48 W/mK |

| Mamello ea asiti | Ka makhetlo a 30 ho feta ceramic, makhetlo a 150 ho feta lesela |

| Botenya | 2.204 g/cm3 |

| Matla a tšepe | 49 N/mm2 |

| Karolelano ea Poisson (Ha ho Yuniti) | 0.17 |

Haeba u batla Machined quartz discs le Machined Bafani ba lipoleiti tsa quartz ba ka tsamaisang mochini o hlophisitsoeng le oa boleng bo holimo lipoleiti tsa quartz, ho kopanaUS